CryoFlowSkid

Continuous kg-Production

Cryogenic Reactions

3 Reaction Steps in 1 System

Fully automated

Ready for Operation

Highlights

- Plug & Produce & Develop

- Continuous kg-Production

- Cryogenic Reactions

- 3 Reaction steps in 1 System

- Fully automated

- Ready for Operation

Operating Conditions

- Temperature: -60 to +100 °C

- Pressure: up to 20 barg

- Hydraulic throughput: up to 100 l/h

- Production capacity: up to 5 kg/h

.

Empty line to generate full width

CONCEPT

The continuous flow reactor is the way out

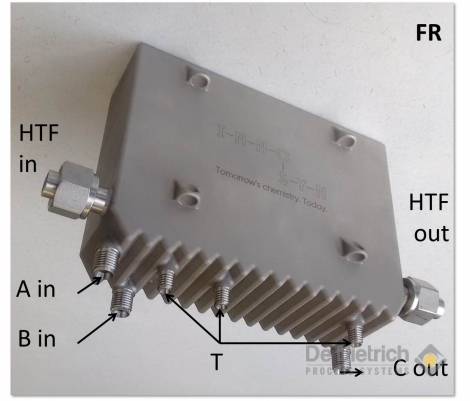

By switching from a stirred batch reactor to a continuously operated flow reactor, the ratio of heat transfer area to reaction volume can be increased drastically. The overall heat transfer can be further improved by choosing material with high heat conductivity and by a thin wall design. The 3D-printing technology for metal reactors allows InnoSyn B.V. a significant flexibility in designing channels for the product and jackets for the heat transfer fluid HTF of the flow reactors FR. Mixing efficiency and heat transfer can be optimized almost free of traditional manufacturing restrictions. From the mechanical side this single item reactor has no internal gaskets, avoids therefore any kind of cross-contamination from the product to the cooling media and provides a high pressure resistance. The high pressure resistance keeps volatile components in the liquid phase and permits a high pressure drop, so that a wide range of hydraulic throughput is possible. By this concept the removal of heat becomes easy so that the reaction can be carried out at a higher temperature level than the comparable batch operatiuon and thus with a higher reaction rate. This results in higher production rates, less diluted purer products and considerable savings of the investment costs for high capacity low temperature cooling equipment.

Empty Line to generate full width

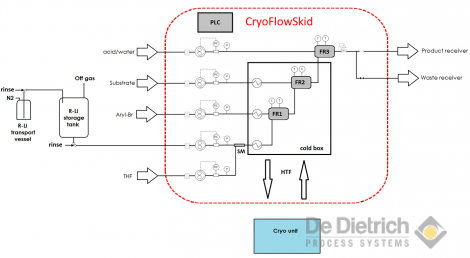

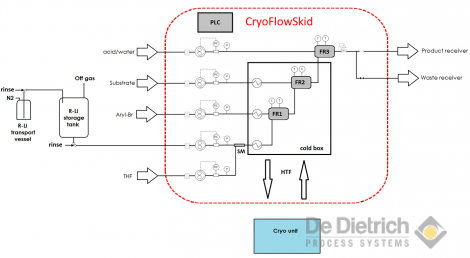

A complete multi-step cryogenic flow reaction system is the solution

Compared with a batch reactor a continuously operated reactor requires more auxiliaries as e.g. pumps and flow meters as well as control devices. In batch mode a potential 2nd reaction step is carried out consecutively in the same batch reactor. In continuous mode a second flow reactor FR2 is required in series with similar auxiliaries as the first one FR1. It is obvious that a 3-step synthesis with a third reactor FR3 becomes as to engineering and project too complex for the daily pilot plant activities. This requires cross-functional and interdisciplinary competences.

.

Function

Plug & Produce & Develop

The design of the CryoFlowSkid permits the production of several kg/h of an organic component by means of a continuous 3 step syntheses with 2 of them in cryogenic mode. Typical production rates of 10%wt solution of the final product are up to 50 kg/h.

The CryoFlowSkid is very compact and ex-protected for zone 2 so that it can be operated in most pilot plant areas.

Beside the connection to feed and product vessels the mobile unit needs only to be connected to the required utilities as electrical power, heating/cooling fluids and nitrogen.

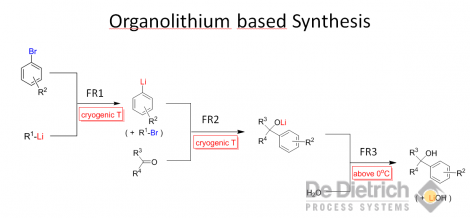

The 3D-printed flow reactors designed by InnoSyn B.V. are made of stainless steel FR1, FR2 and Hastelloy, FR3. The flow chart shows the flow reactors FR and heat exchangers connected in series. The jacketed heat exchangers and flow reactors FR1, FR2 for the two cryogenic steps are to be connected to a cryogenic heating and cooling unit (Cryo unit not being part of scope of supply). Together with their interconnecting piping they are installed in an insulating so called cold box. This avoids their individual insulation and permits quick access for modifications. This simplified exchange of the reactors and heat exchangers provides the flexibility for a quick adaptation of the CryoFlowSkid to different reaction routes and rates. The reactors FR1, FR2 in the cold box can be operated down to -60°C. The jacketed reactor FR3 can be operated separately up to 100°C with an additional heating and cooling unit.

The temperatures and pressures in the reactors are individually measured. The individual flows of the liquids generated by integrated pumps is measured by mass flow meters and used to control the pump rates. The separate non-ex-protected mobile control cabinet is linked by a few 10m long detachable cables to the chemical system. The interface for the controls is a user friendly touch screen. By means of A WINDOWS 10 based soft PLC all measured values are logged and the pumps, control valves, heating and cooling systems controlled. Start-up, operating, standby, and cleaning modes can be set, stored and selected. The degree of automation provides reproducible operation. The amount of measurements, the wide possible operating space and the flexibility of the CryoFlowSkid makes it also perfect for the process development. This is especially advantageous since the process data obtained with this continuous flow skid can be simply and reliably taken for a bigger continuous production scale system.

Empty line to generate full width

.

Application

Simplified API Production with Organometals

Organometal reactions, such as Grignard and Organolithium reactions are known since long in academia and are a proven versatile method in organic chemistry to generate CC bonds. Meanwhile many Organolithium compounds are commercially available so that they don’t need to be synthesized on site any more. Although transportation and storage of these Organolithium intermediates is quite challenging, the number of their applications and total consumption hence increases continuously. Whereas the synthesis routes based on Organolithium intermediates at laboratory scale, even at low temperatures down to -80°C or lower, are somehow feasible easily, they become quickly challenging in bigger scale.

.

kg-Production of APIs or their precursors

The challenge is to keep the safety and selectivity of these reactions high by maintaining the temperature low while a huge amount of heat is generated by the strongly exothermal reaction. The low ratio of heat transfer area to reaction volume in stirred batch reactors, results in products highly diluted in solvents, long cycle times and high costs for cooling equipment with a high capacity even at very low temperatures. This is not only an issue for larger scale production in t/y, but also in kg/d in pilot scale. For example, this is also the case for the production of APIs or their precursors in the pharmaceutical industry for phase I, II and higher. They have to elaborate reliable and reproducible ways to quickly produce some kg of products, avoiding longer periods to develop the pilot scale process from the bench top process.

.

Don’t worry, if you missed on ACHEMA PULSE our session “CyroFlowSkid – Cryogenic Flow Chemistry Made Easy” you can still see it here. Find out within 30 min how to manage strongly exothermic multi step syntheses routes with instable intermediates - Plug &Produce & Develop

Highlights

- Plug & Produce & Develop

- Continuous kg-Production

- Cryogenic Reactions

- 3 Reaction steps in 1 System

- Fully automated

- Ready for Operation

Operating Conditions

- Temperature: -60 to +100 °C

- Pressure: up to 20 barg

- Hydraulic throughput: up to 100 l/h

- Production capacity: up to 5 kg/h