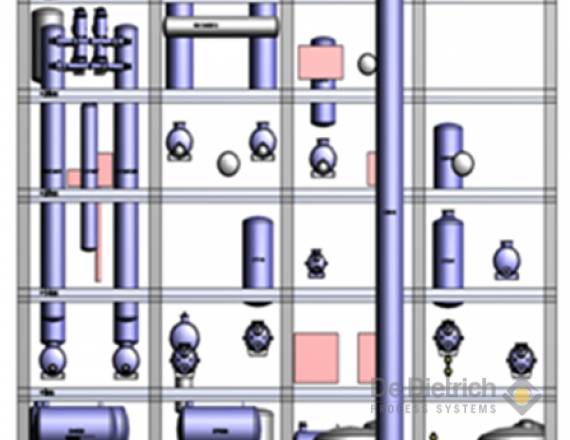

QVF® N.A.C.-S.A.C. / DNT-S.A.C.

Our client belongs to the world largest manufacturers of Polyurethane, in the ranking No.3 after Bayer and BASF.

The Nitric Acid is consumed during the nitration process and the Sulphuric Acid is diluted to ~70-wt%. From 70.000 kg/h waste acid feed remaining organics are stripped out and Sulphuric Acid is re-concentrated to 93-wt% in the DNT-S.A.C. to be reused with new high-concentrated 98,5-wt% Nitric Acid, which is produced from 63-wt% Nitric acid within the N.A.C. – S.A.C. Plant.

The process has been adjusted to customer needs several times, demonstrating our flexibility and competence, reaching low capex and opex. Together with the localization of glass lined items and our local service approach – including the reputation of the DD Wuxi team – we could secure that order. Due to the competition, some of our previous prop-equiment like tantalumn heater, quench columns or glass lined piping are not included up to now. Therefore, we still have to fight later on.

De Dietrich Process Systems developped a process based on NA concentration and SA dinitration for the Specialty chemicals industry and SA concentration