Acid concentration and more

.

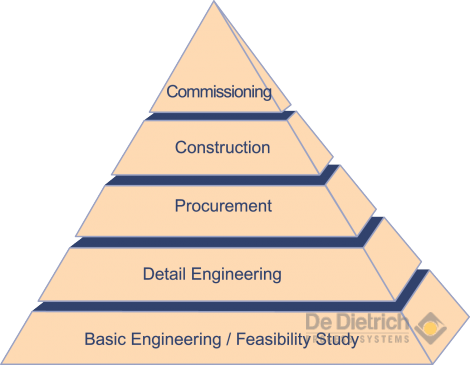

Basic Engineering

- Mass and energy balances

- Trial Experiments in the QVF® pilot plant facility

- Process flow diagram (PFD)

- Preliminary layout of the plant

- Apparatus and pump specification

Detail Engineering

- P&ID

- General arrangement drawing

- Isometric drawing

- Manufacturing drawings

- Valve specification

- E&I Specification

Procurement

- Enquiry

- Award

- Project control

- Acceptance

Construction

- Construction management

- Scheduling

- Interface management

- Troubleshooting

- Acceptance coordination (PED)

Commissioning

- Loop check

- Test run with water

- Commissioning

- Performance test

Test facility

Individual process steps can be tested in the test facility if it is not possible to fall back on DDPS know-how for new products or processes. Therefor DDPS has a filter/drying test facility at Rosenmund site and one for chemical engineering at QVF® in Mainz.

The customer test facility is used to develop company-own components and processes as well as for testing and optimising customer-specific tasks. Also the production of small amounts of samples is possible.

Main focus acid concentration

Mineral acids are very important in chemical procedures. Not only as a reaction participant and catalyst, but also as an aid, as in the case of sulfuric acid for drying gasses or during extractive distillation, but also as a cleaning agent as used in the electronic industry.

Through our experience with corrosion-resistant materials, we have process know-how in mineral acid handling and offer you in part our own processes, such as for example the energy-saving concentration of nitric acids (USA 10/296,297).

By the combination of borosilicate glass and glass-lined steel you get most of the key process equipment from one source. We offer our know-how in:

Product recovery and product purification

- Solvent recovery by evaporation, distillation and rectification like MDC, NMP, DMF, alcohols, Cleaning Solvent, etc.

- Rectification of binary and multi-component mixtures (e.g. epichlorhydrin)

- Production of absolute alcohol by extractive or azeotropic distillation

- Recovery of organics by solvent extraction: phenol, pyridine, DMF, NMP

- Recovery of metal salts and acids by solvent extraction: acetic acid, thioglycolic acid; Ferric chloride, ammonium molybdate

- Dehydration of organics (amines, THF) by caustic packed bed adsorption

- Purification of natural extracts (e.g. essential oils)

Waste water treatment

- Stripping of partly miscible components (toluene, chloroform, MDC etc.)

- Stripping of ammonia

- Extraction of high boiling impurities without recovery

- Multiple-effect evaporation of waste water with or without solvent recovery (e.g. NMP, DMF, phenol

Exhaust gas purification

- Drying of SO2 or Cl2 using sulphuric acid

- Absorption of HCl, HBr, SO3, and Cl2, Br2, SO2

- Combined absorption of HCl and SO2

- NOx-Absorption

- Absorption of ethylene oxide or ammonia

- Absorption and recovery of volatile organic components VOC

- Solvent Condensation Unit

Recovery, Concentration and Purification of Mineral Acids

- Sulphuric Acid Dilution

- Sulphuric Acid Concentration

- Nitric Acid Concentration

- Denitration and recovery of mixed acids from nitration plants

- Hydrochloric acid recovery

- Concentration of HCl by extractive distillation or two pressure process

- Purification of spent acids from etching processes

- High purified (electronic grade) acids: HCl, HNO3, H2SO4

Reaction with halogens / HCl

- Bromine recovery from sea water

- Debromination/ bromine recovery from salt solutions

- Iodine Recovery

- NaOCl Production

- H2S – Gas Production