Optimizing Process Efficiency with De Dietrich Flextech Stainless Steel Reactors: A Closer Look

Superior Material Quality for Unmatched Durability

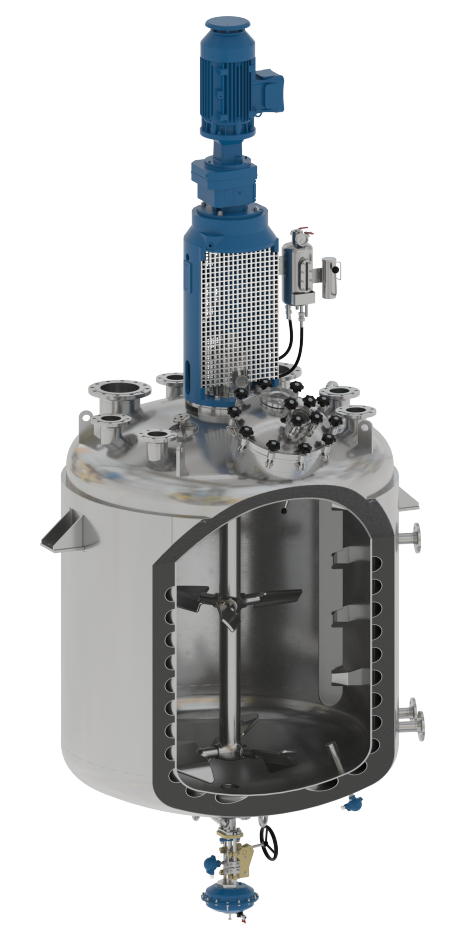

The foundation of Flextech reactors lies in their construction from premier austenitic stainless steel grades (1.4404, 1.4301, 1.4539, 1.4571) and nickel-based alloys such as Hastelloy C22 and C276. These materials are not just about durability; they're about ensuring your reactor withstands the harshest conditions, offering superior corrosion resistance that is essential for handling aggressive substances safely and efficiently.

Exceptional Surface Finish and Design: The Hallmark of Quality

A step ahead in design, Flextech reactors boast a mechanically polished product contact surface of Ra ≤ 0.8 µm and external surfaces polished to Ra ≤ 1.6 µm. This meticulous attention to surface finish ensures optimal cleanliness and minimizes product adhesion, critical for maintaining product purity. Compliant with EN 13445 and carrying the CE marking as per 2014/68/EU (PED) Module G, these reactors not only meet but exceed the highest safety and quality standards.

Advanced Working Parameters and Features for Versatile Operations

Flextech reactors are engineered to operate within a broad temperature range of -25 to 200°C and pressure settings from -1 to 6 barg. Their nozzle connections, compliant with EN1092-1 type 11 B PN16, and ATEX conformity for explosion-proof design, underscore their adaptability to diverse operational needs and regulatory environments.

Cutting-edge Agitation and Temperature Control for Precision Processing

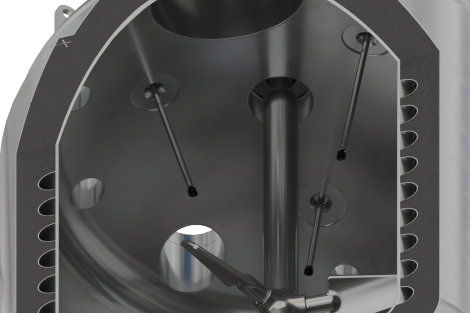

Featuring an array of agitator types derived from De Dietrich’s esteemed glass-lined portfolio, the reactors offer unparalleled mixing efficiency. With options for mechanical seals tailored to various process requirements, and precise temperature control facilitated by dual Pt100 probes, these reactors guarantee optimal reaction conditions, enhancing product quality and process reproducibility.

|

BLADES WITH ADJUSTABLE ANGLE OF ATTACK

individually repleacable blades with an internal |

BOLTED BLADES

Blades individually bolted |

MONOBLOCK AGITATOR Blades welded to the shaft

|

Enhanced Clean-In-Place (CIP) System and Unique Features

The dedicated CIP nozzles and innovative design elements significantly simplify cleaning processes, validated by the riboflavin test for cleaning efficiency. Unique features, such as heated baffles and laser volume markings, not only contribute to operational efficiency but also ensure ease of maintenance and process control.

Customization and Optional Features: Tailored to Meet Your Needs

Understanding that every process is unique, De Dietrich offers extensive customization options for the Flextech reactors. From cryogenic temperatures to increased surface smoothness and compliance with various design codes, these reactors can be precisely tailored to meet specific process requirements, ensuring a perfect fit for your operational needs.

Embracing Sustainability and Industry Applications

Flextech Stainless Steel Reactors are designed with energy efficiency and sustainability in mind, making them an ideal choice for industries committed to environmental responsibility. Their versatility makes them suitable for a wide range of applications in the pharmaceutical, biotech, and chemical processing sectors, where reliability, efficiency, and compliance are paramount.

Transform Your Operations with Flextech Reactors

De Dietrich’s Flextech Stainless Steel Reactors are more than just equipment; they are a testament to innovation, designed to enhance your process efficiency, reliability, and safety. Whether you're looking to upgrade your existing operations or embark on new ventures, these reactors offer a solution that aligns with the highest standards of quality and performance.

Take the Next Step

Discover how De Dietrich Flextech Stainless Steel Reactors can revolutionize your processes. Contact our experts today for personalized advice or download our Flextech dedicated brochure for an in-depth exploration of our solutions. Embrace innovation and precision with De Dietrich, and propel your operations into the future.