How wall-mounted baffles can boost glass-lined reactor performance

Baffles are essential to proficient blending, solids suspension and other mixing objectives.

There are various ways to promote a better mixing pattern through the incorporation of axial and radial circulation.

If a tank remains unbaffled, a mixer can be mounted off-center or at an angle. In some cases, this provides a suitable mixing solution; however, this method of mixing produces unbalanced loads that can have a negative impact on the agitator shaft. Additionally, the viscosity and specific gravity of the product can require a more rugged gearbox and bearing which increases costs. For these reasons, installing baffles is typically the preferred solution to improve mixing.

BAFFLES DESIGN

Baffles come in many variations and based on your unique process objectives and product characteristics one design may be more suitable than another. For the most part, though, baffles have a long, flat shape and are either nozzle-mounted via the top head of the reactor or mounted to the wall of the vessel.

Nozzle-Mounted

Traditional glass-lined baffles are designed to hang from the top head of the vessel’s flanges to ensure the integrity of the vessel lining.

While this offers effective mixing, there are limitations and inefficiencies created by this arrangement. Since mounting flanges are needed for process monitoring, insertion of cleaning devices and the introduction of reactants, no more than two baffles are typically used due to the limited space in the head.

Wall-Mounted

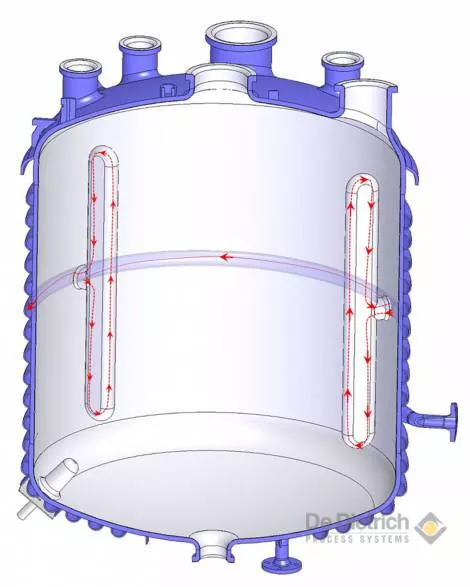

The wall-mounted baffle design (called OptiMix®) solves the issues faced by traditional baffle installations by welding the reactor wall prior to coating all steel surfaces with glass. This new configuration employs three glass-lined baffles, rather than the single baffle used in conventional glass-lined equipment.

This results in many advantages, including:

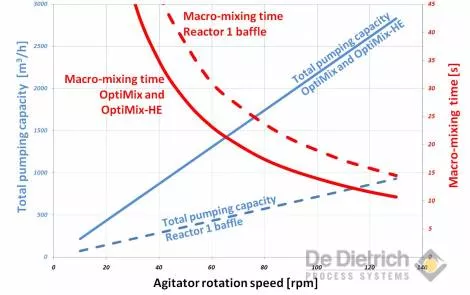

- Improved Mixing: Mixing times are reduced by approximately one-third through improvements in heat and mass transfer, solids suspension and distribution, gas dispersion and gas flow rates.

- Minimized bending loads: The symmetry of the three baffle/three mixing blade combination reduces the flexure that can deflect the agitator shaft and reduce seal life.

- Elimination of space top head space constraints: The absence of a baffle flange mounted on the reactor head frees up one or more nozzles for other usage

- Easier cleaning between batch operations: In addition to poor mixing, vortexes also create an undesirable splashing effect that leaves liquid on the reactor walls above the surface level. This is particularly problematic in heated reactors, as the droplets quickly dry and leave product residue on the vessel walls that is difficult to remove and usually requires manual intervention for proper cleaning. The elimination of the vortex with the OptiMix® also eliminates product build-up on the interior walls.

OPTIMIX® - HE REACTOR

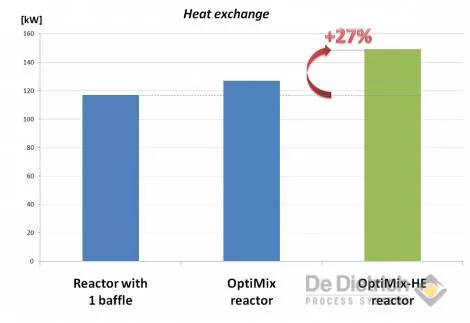

The range of the OptiMix® reactors has expanded to provide improved heat transfer and reduced processing times. This new design, OptiMix® - HE, circulates the thermal fluid contained in the half-coil reactor jacket through the baffles. This results in an increased heat transfer area of 25% or more enabling better homogeneity, faster thermal management and shortened cycle times.

The graph below shows the heat exchange comparison between a reactor with one nozzle-mounted baffle, the OptiMix® reactor, and the OptiMix® - HE reactor.