Pioneering Glass-Lined Technology Since 1870

De Dietrich has been setting the global standard for glass-lined equipment since 1870. Our in-house enamel production in France ensures superior durability, corrosion resistance, and traceability across all solutions.

Trusted by the chemical, pharmaceutical, and process industries, our DD3009 enamel guarantees long-term reliability, easy cleaning, and compliance with the most stringent regulations.

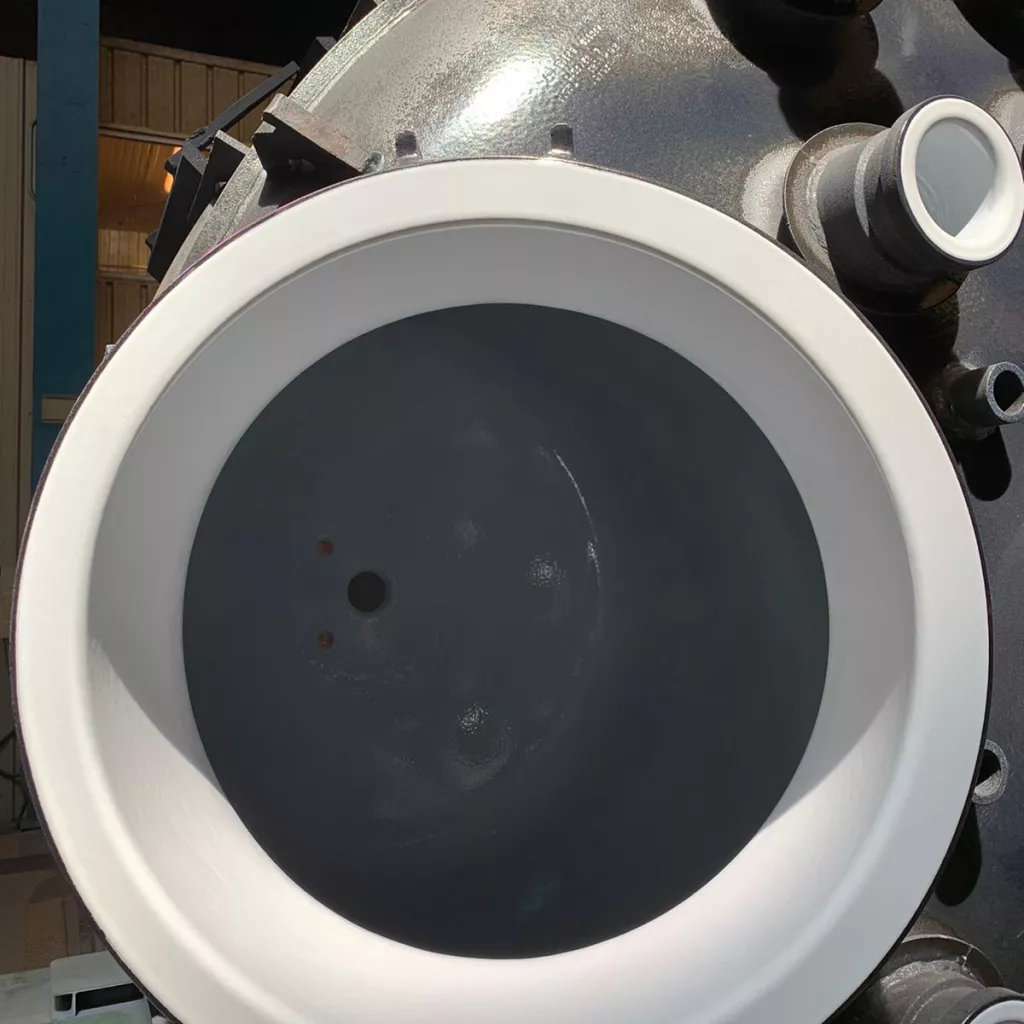

Why Choose Glass-Lined Technology?

Glass-lined equipment is the ideal solution for corrosion resistance, purity, and long-term durability in demanding processes. De Dietrich is a leader in enamel technology, offering glass-lining solutions that provide:

Exceptional corrosion protection in aggressive chemical environments

Non-stick, easy-to-clean surfaces for contamination-free processes

High mechanical & thermal shock resistance, extending equipment lifespan

Global compliance (cGMP, FDA, EMeA, ICH, CE 1935/2014) for pharma & food industries

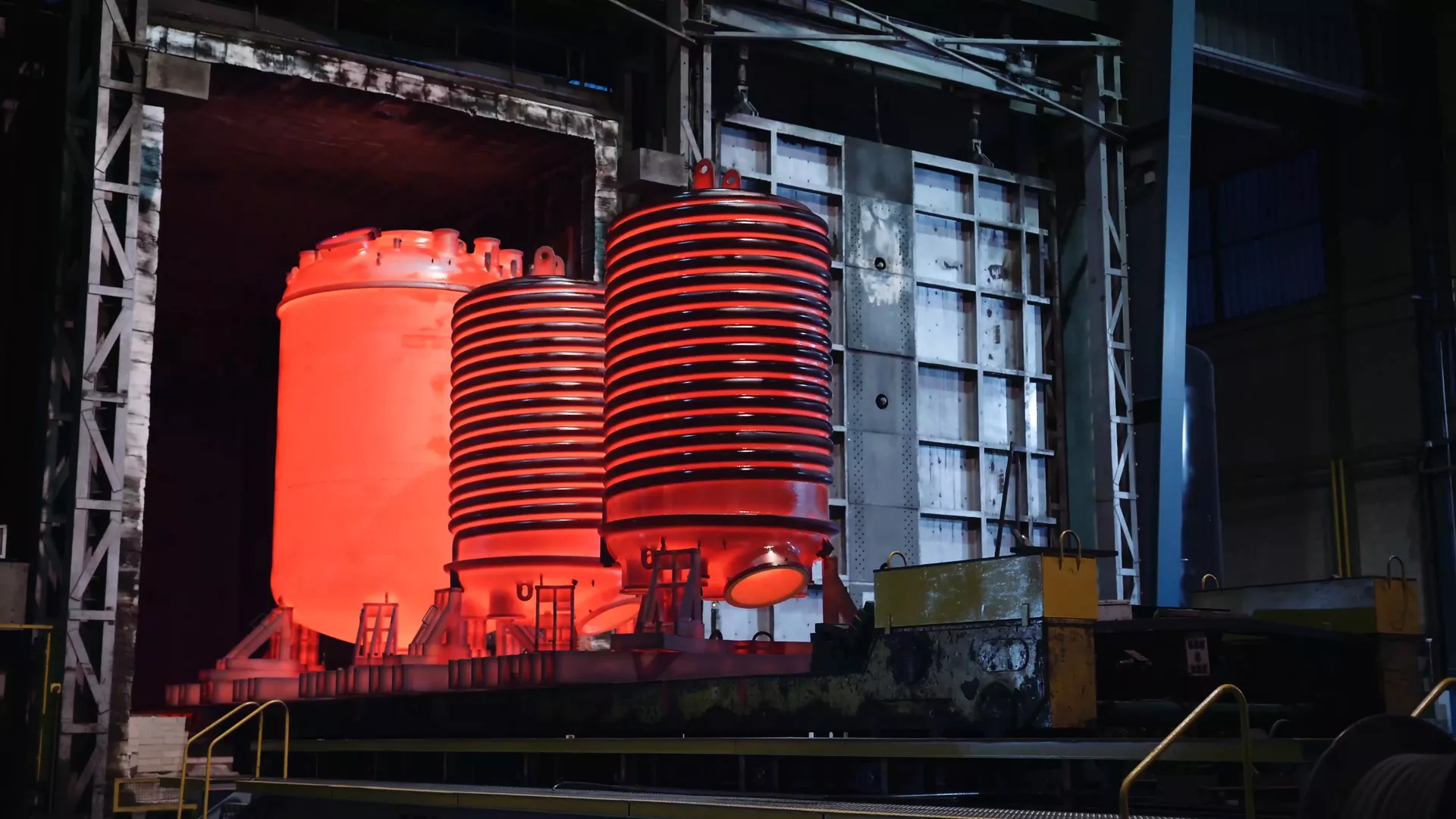

The Glass-Lining Process

The quality of glass-lining is as much about the enamel formula as it is about the application process. De Dietrich manufactures its enamel in-house to ensure:

- Perfect homogeneity & purity for consistent performance

- Multi-layer spray & firing technique to achieve precise thickness

- Strict quality control (spark testing, thickness measurement, visual inspection)

- A smooth, polished surface free from defects or irregularities

By mastering both enamel production & application, we guarantee the highest reliability on the market.

Expertise That Sets Us Apart

World’s leading glass-lining manufacturer with over 150 years of expertise

One single enamel quality across all De Dietrich equipment worldwide

Advanced process control ensuring maximum corrosion resistance

Highly skilled, experienced sprayer teams for optimal coating application

We're here to help

Looking for the most durable, high performance glass-lining solutions?

Our experts are ready to assist you in choosing the right enamel for your processes.

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.