Recovery of High boiling organics from Waste Water

- Waste water cleaning -

- Product recovery -

- Minimum energy consumption -

The combination of extraction and distillation permits a low energy consuming recovery of valuable products from process waste water streams

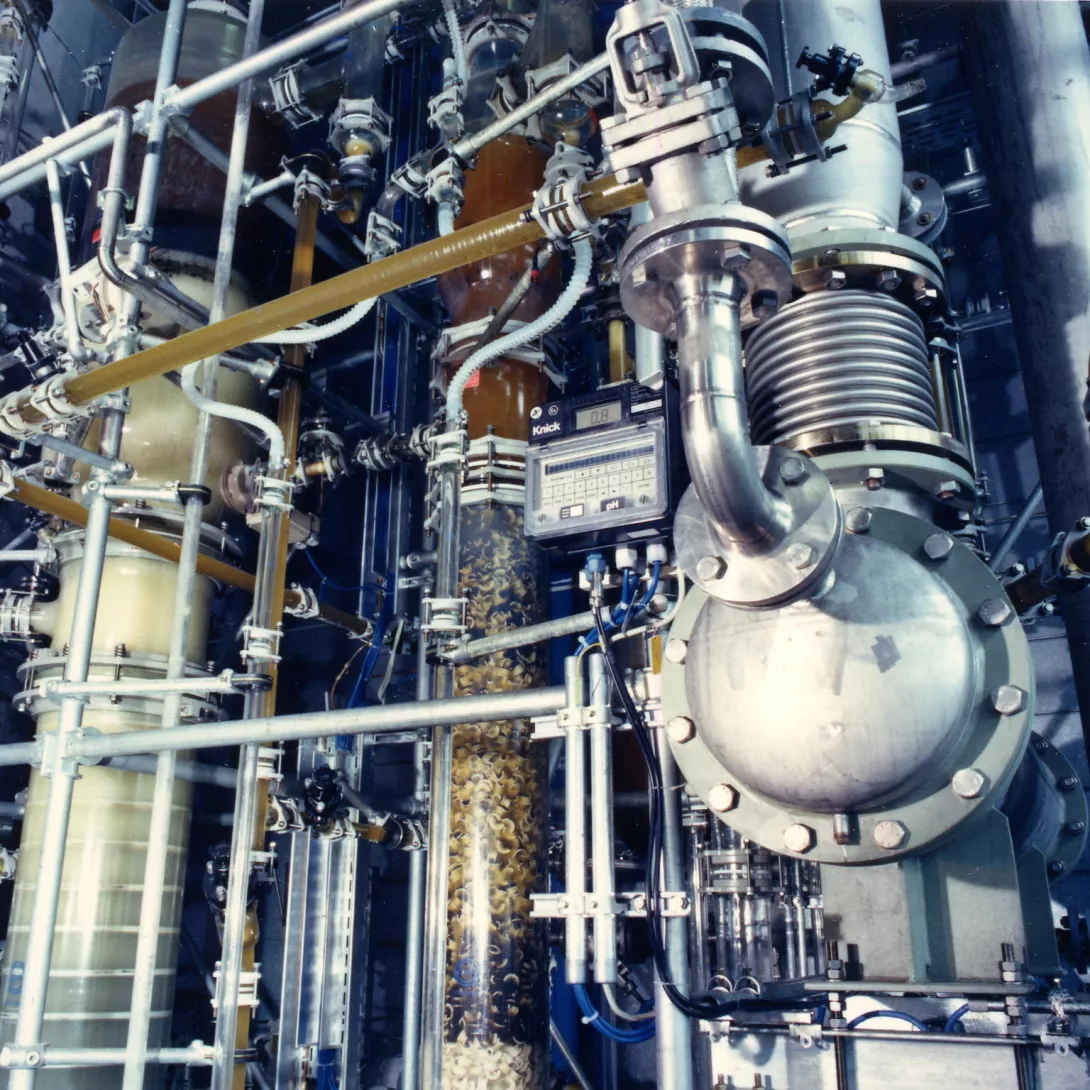

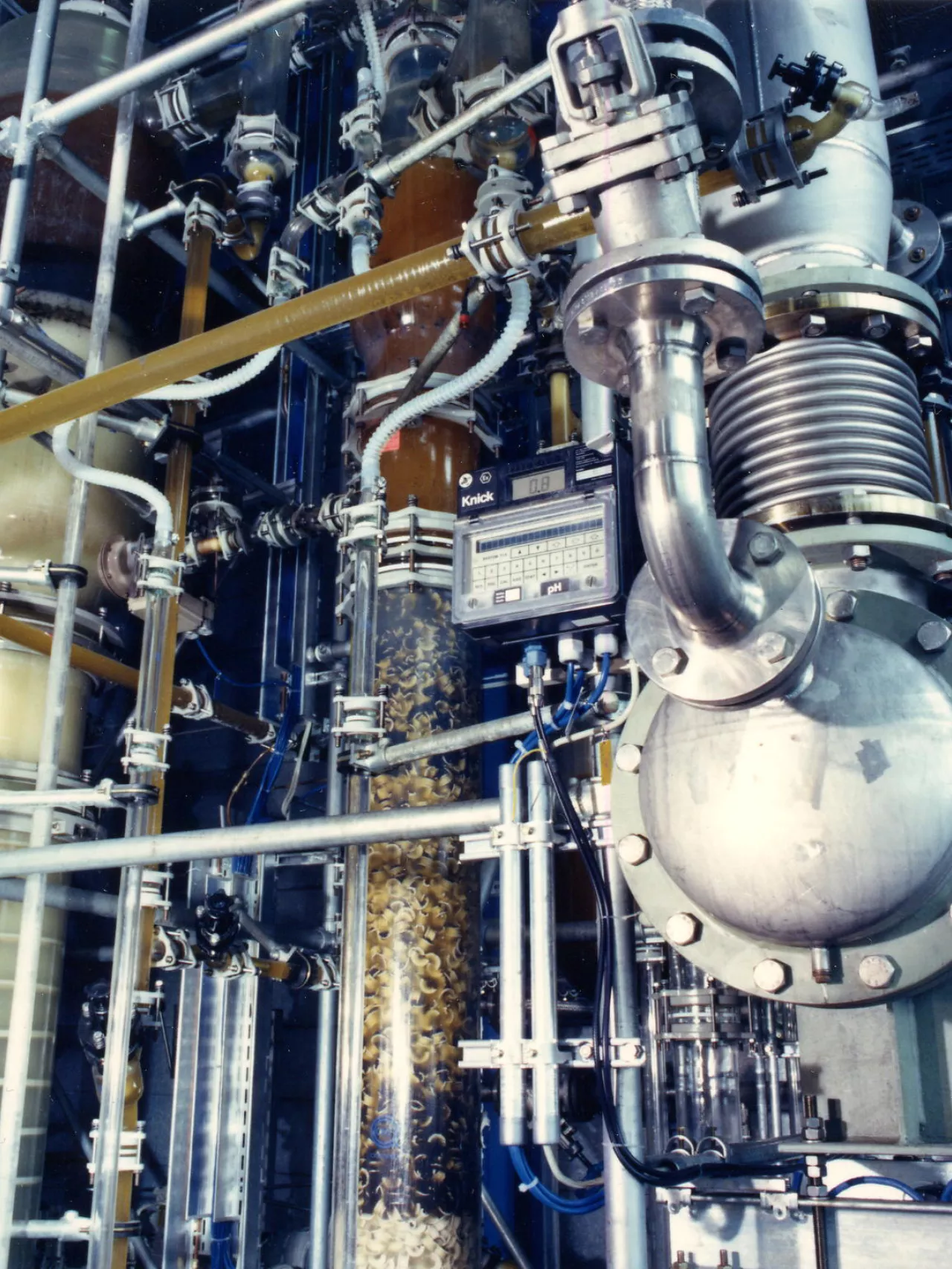

The figure on the left shows: Head vessel of extraction column

DESTROY OR RECOVER?

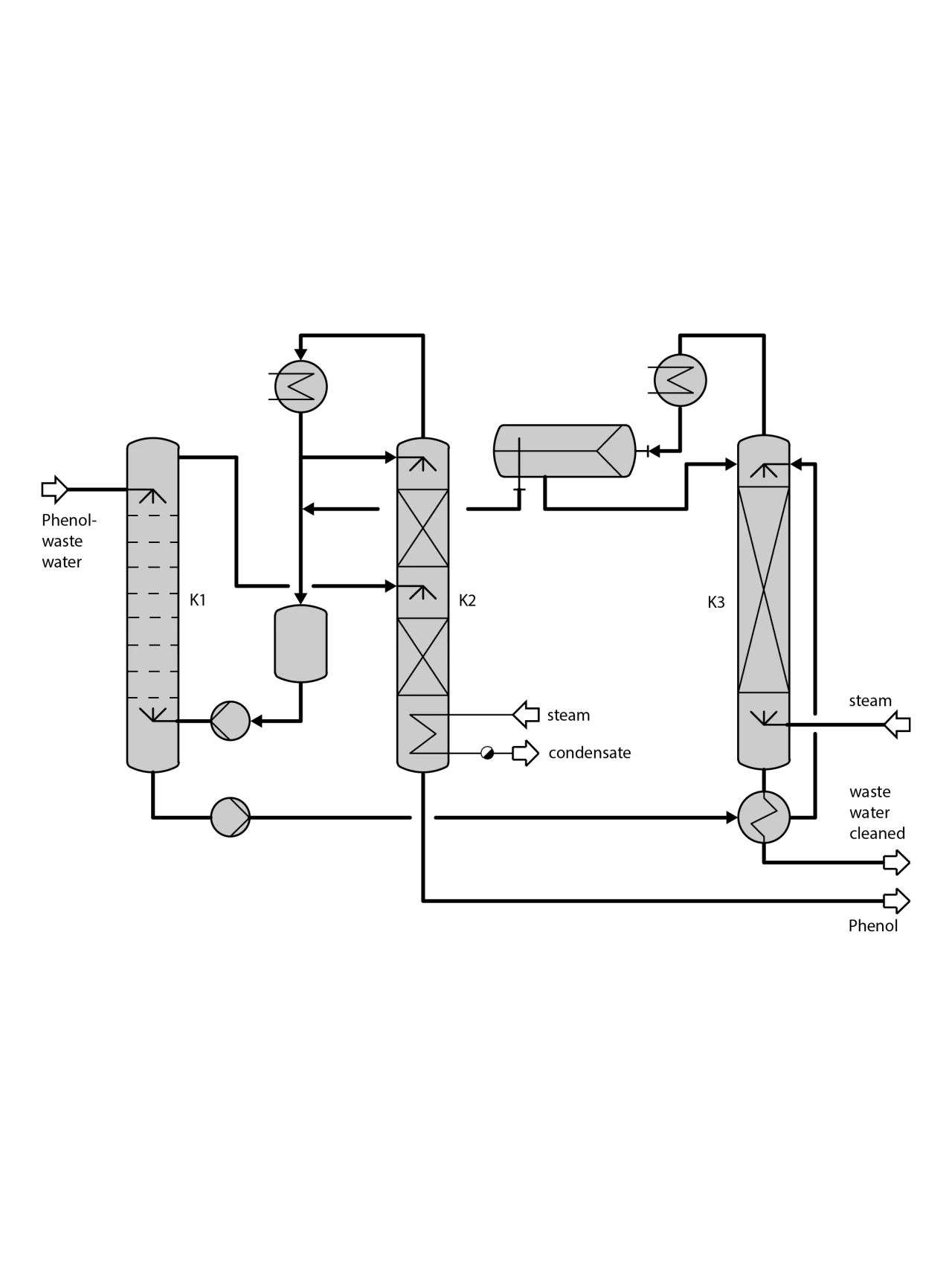

Industrial waste water often contains high boiling solvents, such as phenol or dichlorobenzene, and so cannot be discharged into a sewage treatment plant without reprocessing and cleaning. Since destruction through burning is not only a bad alternative ecologically but also too costly due to the high water content, the preferred way is phenol recovery with simultaneous cleaning of the waste water until it can be discharged into the sewage treatment plant. The example of phenol is used to describe the QVF® method used repeatedly by De Dietrich Process Systems. The phenol content, which depends on the process, is normally 2-12%. The low phenol concentrations eliminate separation by distillation, in which the water is evaporated out, due to the high energy requirements. Here, extraction offers the decisive advantage. Methylisobutylketone (MIBK), an extracting agent, removes phenol from the waste water in the extraction column K1. The charged extracting agent is cleaned again in the distillation column K2 and returned to the bottom of the extraction. The phenol accumulates in the bottom of the subsequent rectification (column K2) and can be used again in production.

While the waste water flowing out of the extraction K1 may be free of phenol, it carries along traces of the extracting agent, which are recovered in the stripper K3. The MIBK/water azeotrope accumulates at the head of the column, where it is separated in the separator B1 into the light MIBK phase and the heavy water phase. Since the distillation column K2 is operated without water, indirect heating is planned here, while direct steam can be introduced into the stripper.

Figures: Sieve plate extraction column and distillation column DN450 and Phenol recovery flow sheet

ADVANTAGES OF THIS SYSTEM CONCEPT

The planned heat recovery in the waste water stream and the use of dephlegmators make the overall process energetically favorable and appropriate for the ecological requirements applicable today. With phenol content in the waste water of less than 5 ppm, the water can be discharged into the biological sewage treatment plant. The extracting agent circulates and is not consumed to a noticeable extent. The recovered phenol can be used again in the process.

WHO NEEDS PHENOL RECOVERY?

Phenol waste water accumulates in many areas of plastic and resin production and in the production of alkylated phenols. The waste water volumes to be processed range from 0.5 m³/h up to 10 m³/h, whereby the chosen extraction unit depends on the waste water volume and the attendant material. With greater volume streams, extraction is performed continuously in serially connected mixer-settlers, since the technical effort is then more favorable than with the pulsed sieve plate column.

EXAMPLE OF A BUILT SYSTEM

The system shown in the illustrations processes waste water stream of 4 m³/h. In this case, we have chosen a pulsated sieve plate column DN400 with 105 plates for the extraction. The distillation column DN500/DN450 with ordered packing works at a pressure of 0.3 bar abs. The waste water with the phenol removed, lightly overheated via a flash tank, and enters the stripper DN450. The scope of supply contained the system with measurement and control devices, vacuum generator, vessels and receivers and the performance run with original product. The special difficulty with every waste water cleaning lies in the attendant materials, whose effects on the main process can be critical. The feed can contain suspended matter, cresols, acetone, formaldehyde or methanol. In the system shown, for example, suspended matter collects in the extraction head and must be continuously fed out. Cresols crystallize at low temperatures so that, when auxiliary heating is lacking and the pipeline layout is unsuitable, a blockage of the system through solids must be feared. The lightly volatile solvent acetone, methanol and formaldehyde, which the waste water also contains, could be removed by means of a preceding stripper. Experience with the built systems has shown that it is precisely the investigation of secondary materials in our test facility that contributes to an optimal system concept.

You have questions?

Our teams are ready to collaborate with you and provide solutions for your projects.

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.