Hero

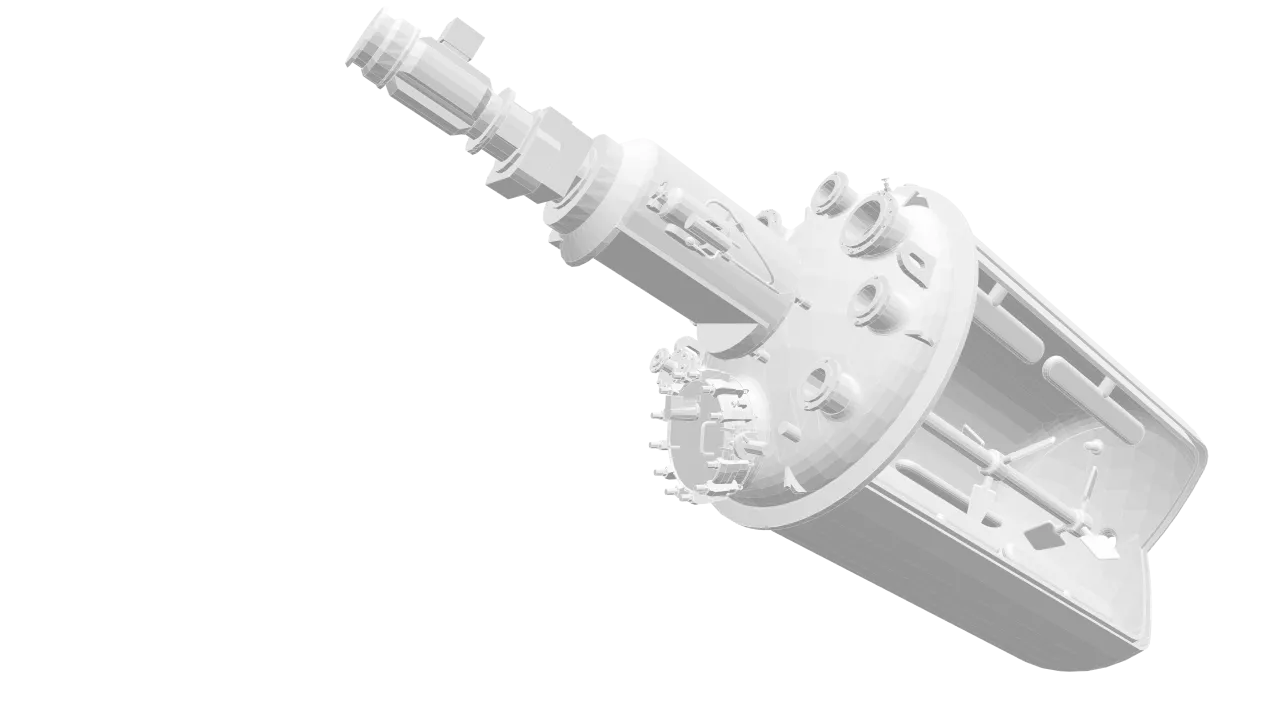

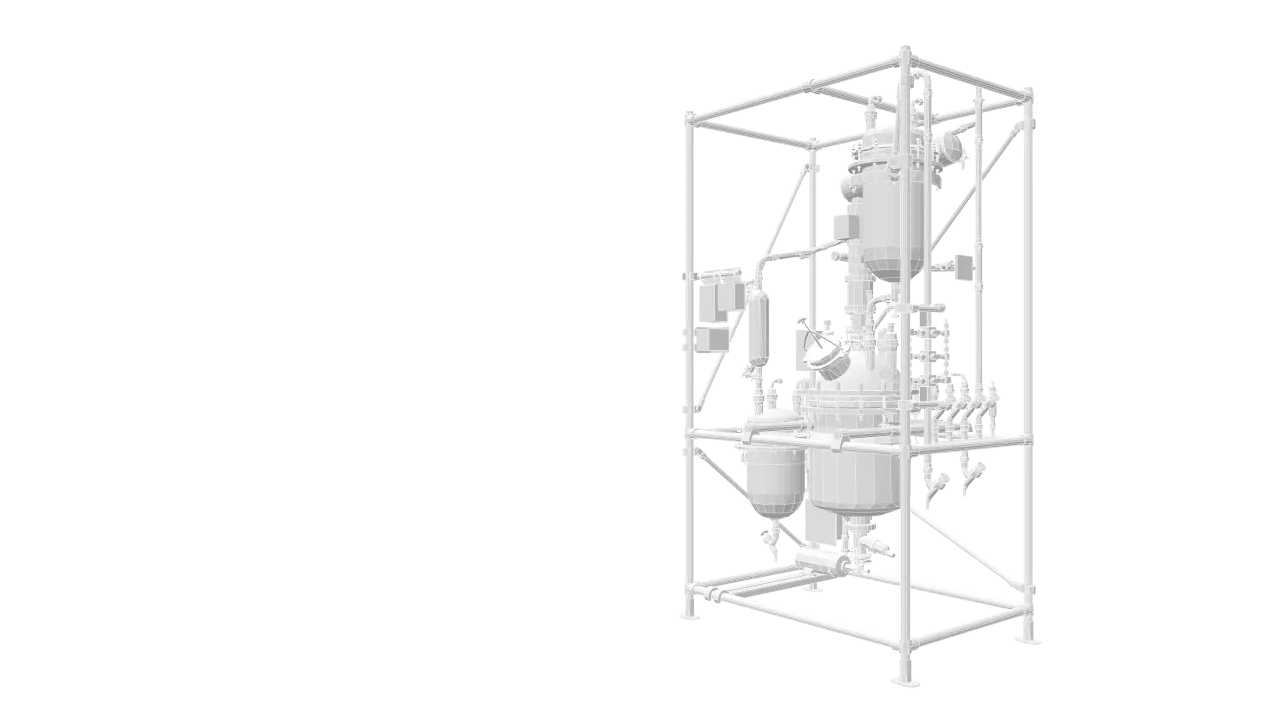

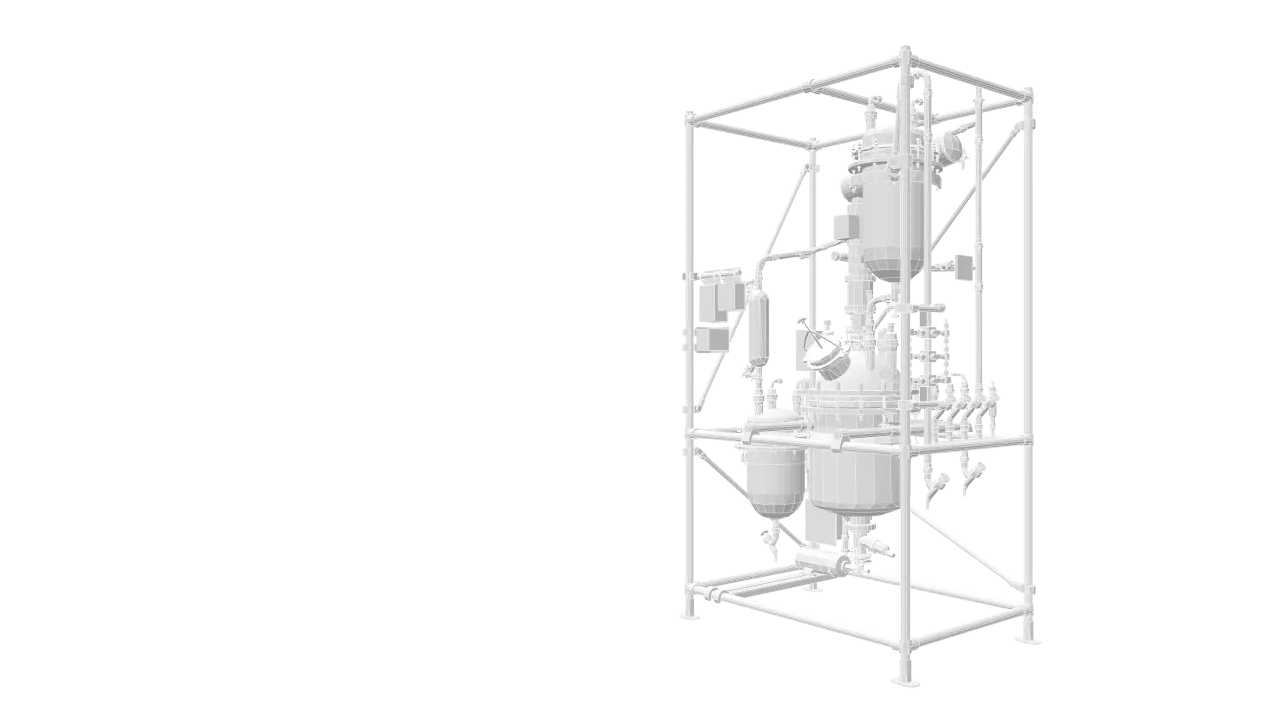

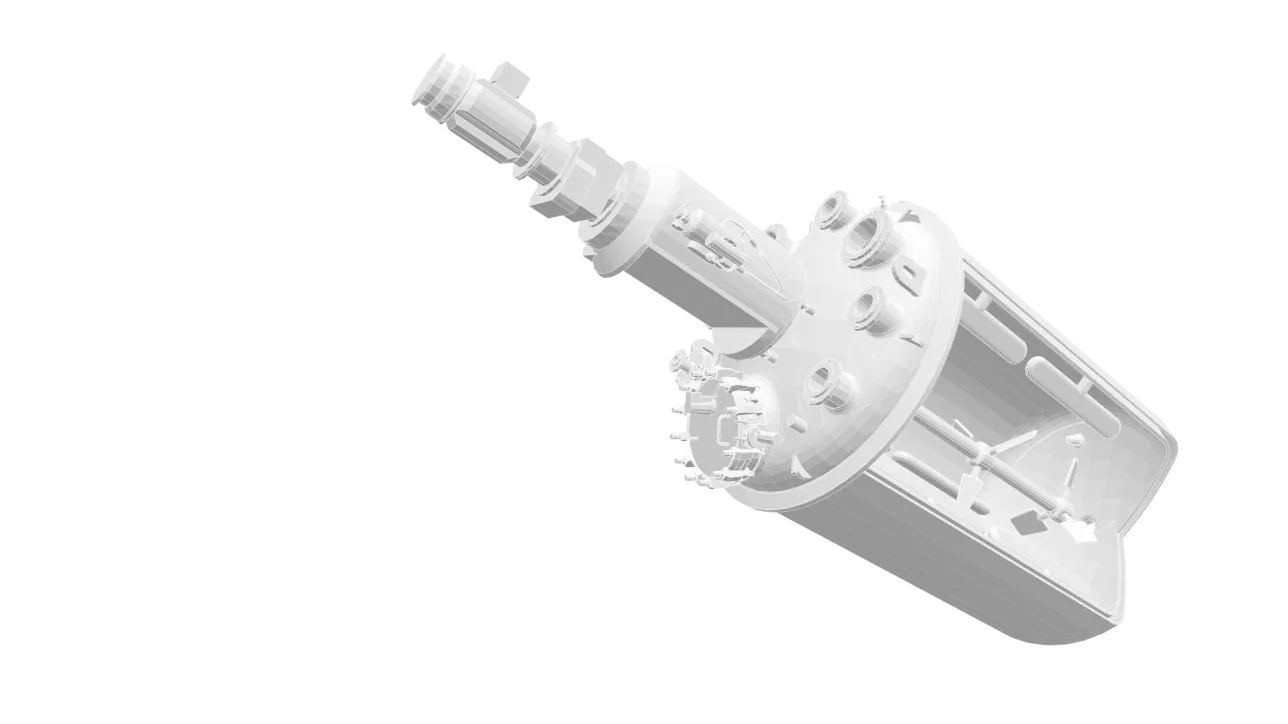

Universal Reactor

The Universal-Reactor, the ideal to solve large-scale synthesis

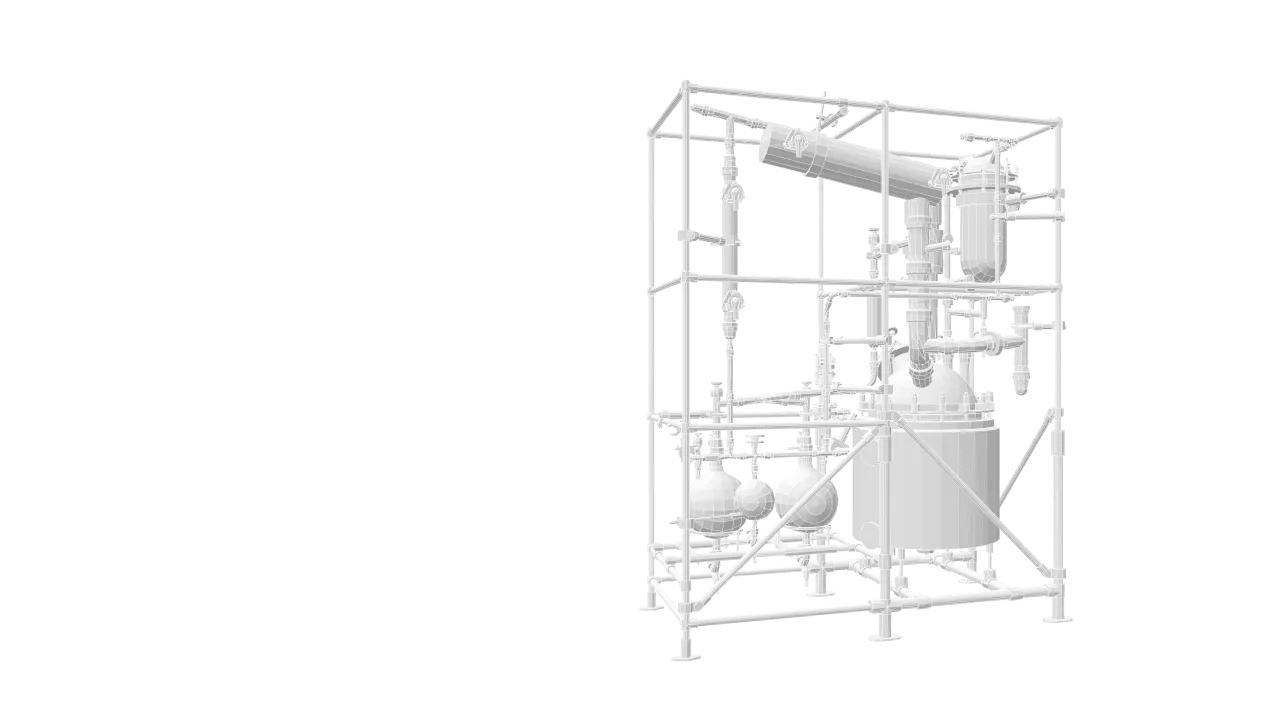

Glass Reaction / Agitation

Pharma Reaction System

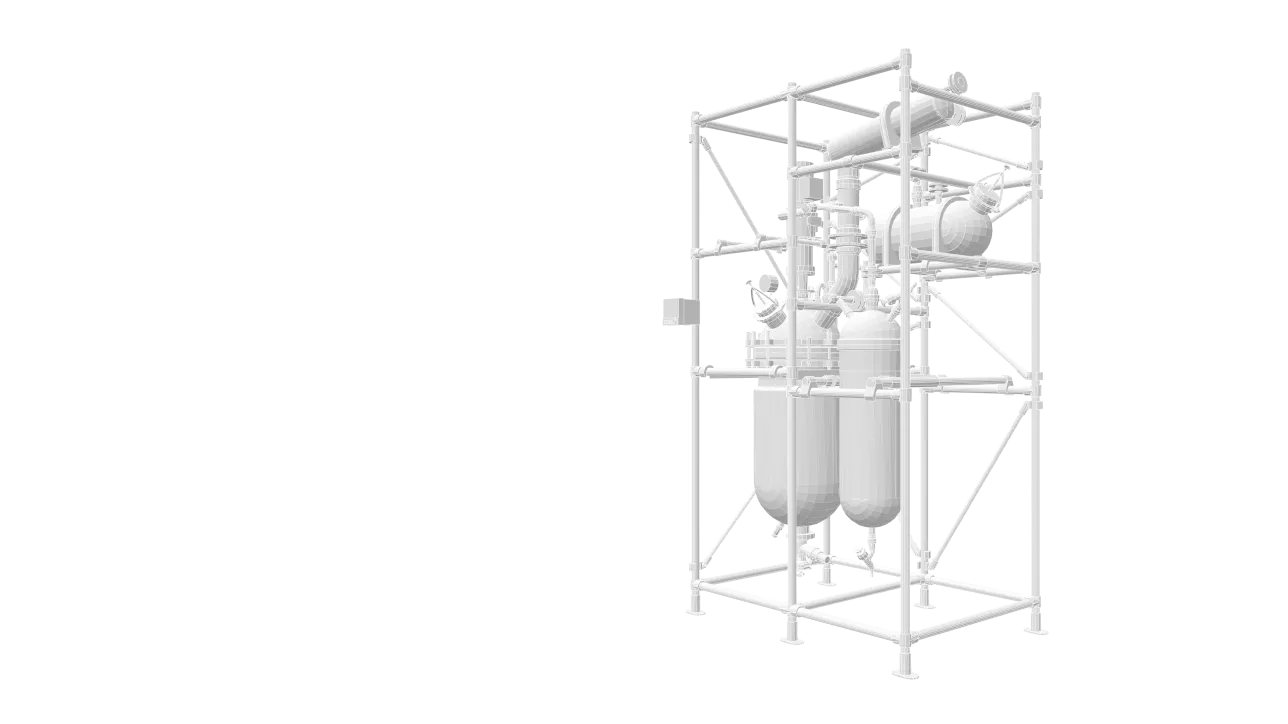

Pharmaceutical applications have guided the design of this equipment

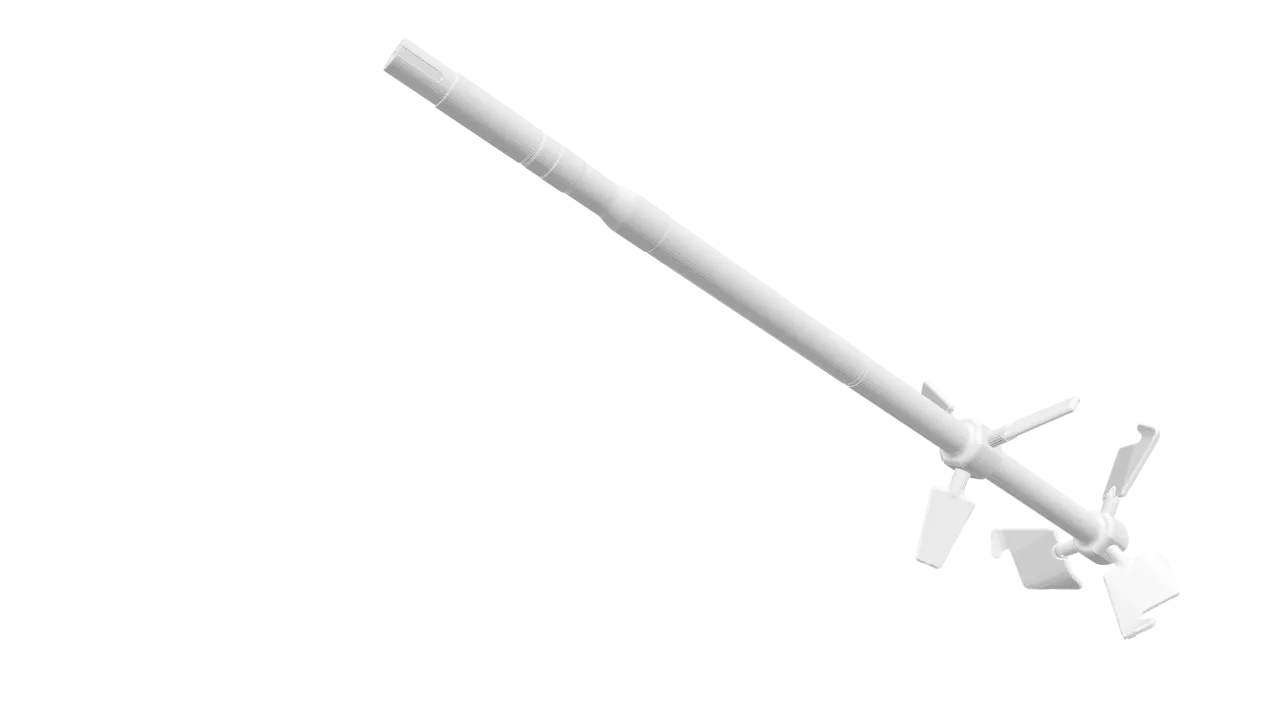

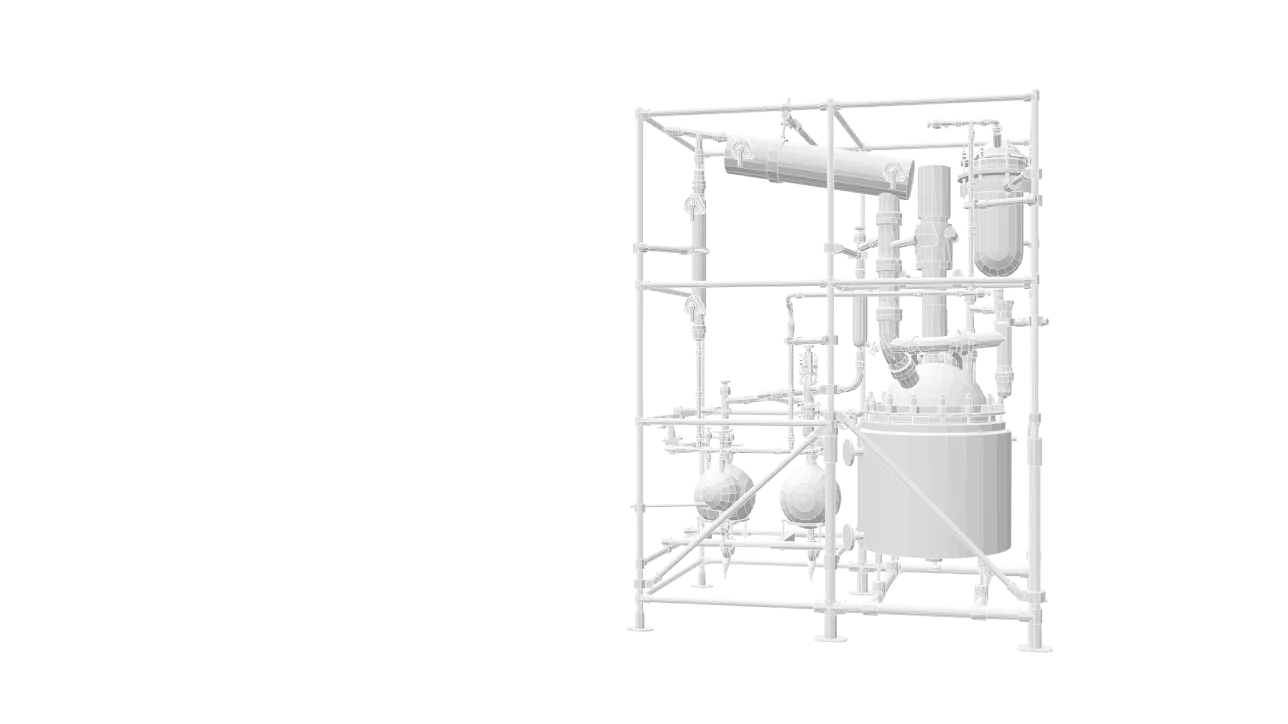

GlassEnamel Reaction / Agitation

Glass-lined reactors

The DIN range is well know across the industry for its amazing specifications

Enamel Reaction / Agitation