Glass-lined reactors

De Dietrich can provide glass-lined reactors to meet a wide variety of chemical processes, volume requirements (from laboratory scale and pilot plant sizes up to very large production units), incorporating local design and international code requirements (ASME, DIN, GB150, JIS...)

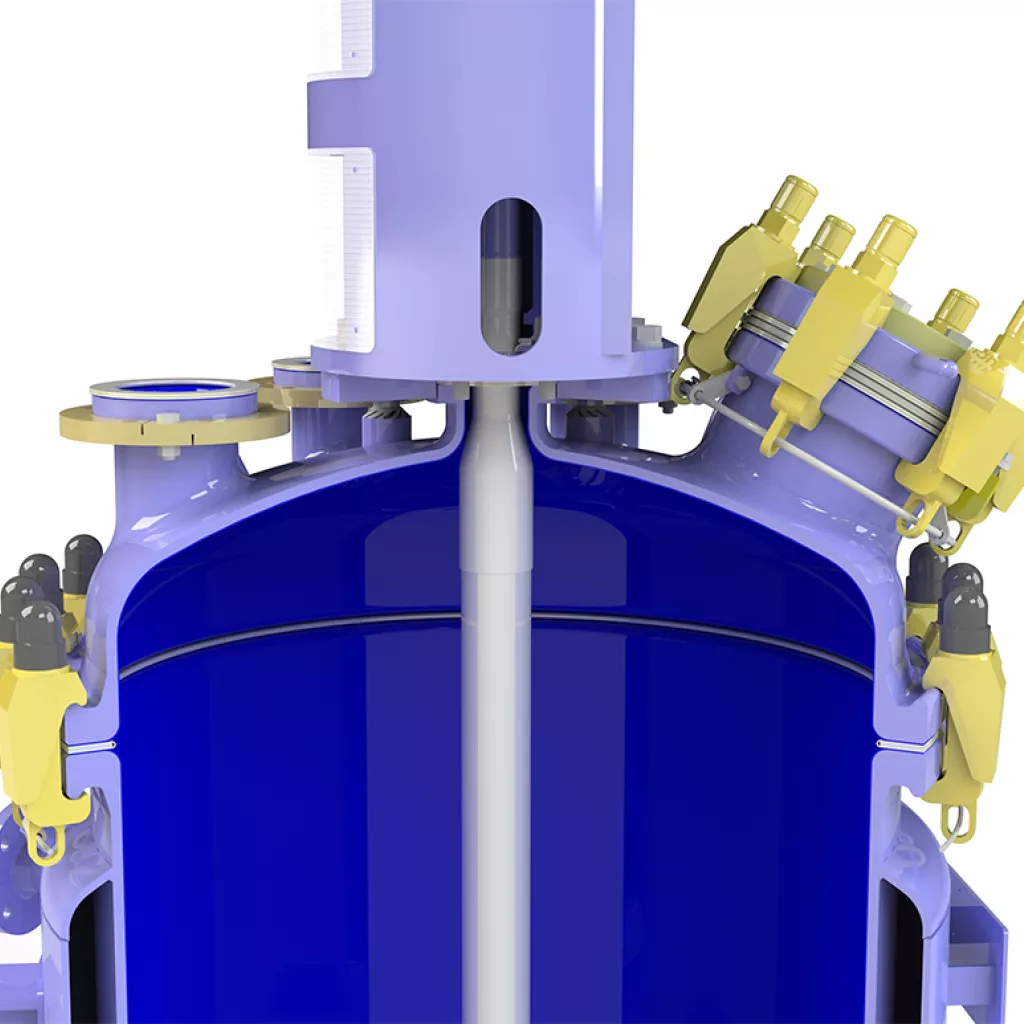

De Dietrich glass lined reactor

Thanks to the properties of our enamel DD3009, all our reactors have excellent resistance to corrosion, smooth non-stick properties and non-catalytic inertness.

They can be designed for high versatility in multiproduct applications, or specialized to optimize a specific processing requirement.

We cover all the standard range of DIN reactors: AE, BE, CE, and are able to customized them as per your requests and operating conditions.

Tailor made reactors

To match your requirements, the product range has been extended with capacities from 63 liters up to 110 m3.

On request, the following alternates can be supplied:

- Execution for low / high temperatures and pressures

- Exterior half coil in welded half-pipes, instead of the jacket, allowing the use of heating fluids at high pressures. Also double half coil for heating and cooling by separate circuit

- As an option, we can provide pre-insulated reactor for time and trouble saving on site

The polyvalence and reliability in every circumstances

Our glass-lined reactors are widely used in the chemical, pharmaceutical, and food processing industries due to their unique properties and versatility. Some of the main applications and uses of glass-lined reactors:

Chemical: Acid and alkali reactions, hydrogenation, polymer production, chemical synthesis, polymerization, coatings, adhesives, fertilizer, explosives...

Pharmaceutical: API (Active Pharmaceutical Ingredient), drug formulation,...

Food & beverage: Fermentation, enzymatic reactions, and flavoring production,...

Environmental Protection: Wastewater treatment, recycling,...

Petrochemical: Oil refining,...

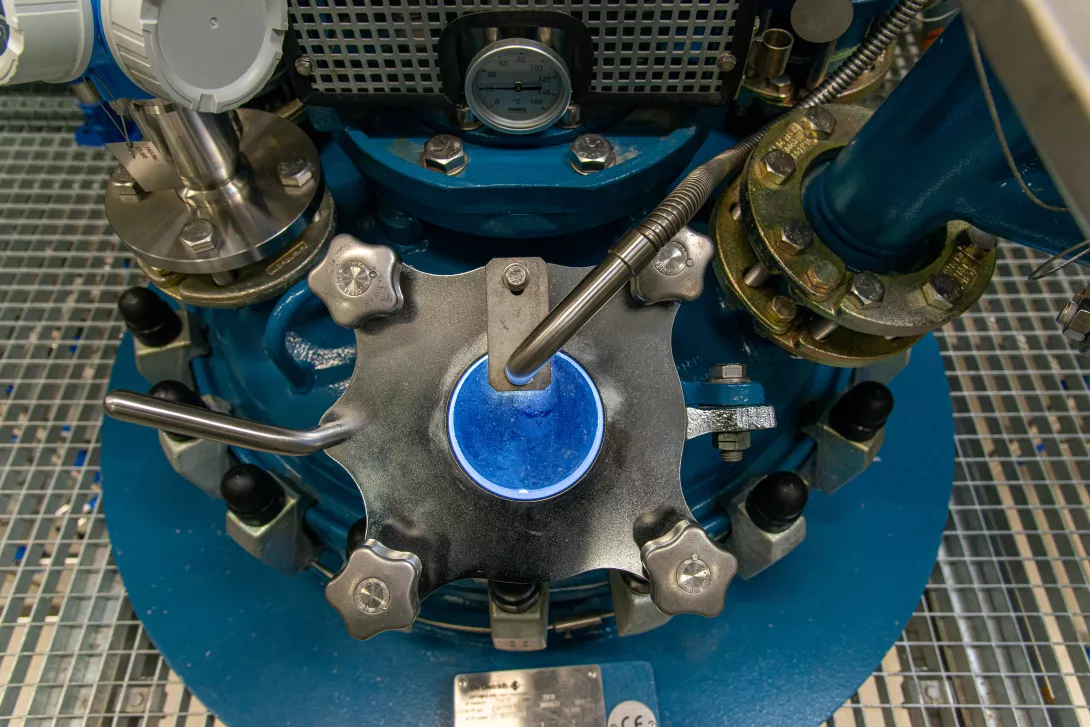

Glass lined reactors installation

You have questions?

Our teams are ready to collaborate with you and provide solutions for your projects

Document to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.