Chemical Process Expertise

The defence and energetic-materials industry relies on demanding chemical processes where nitration, acid recovery, NOx treatment and thermal control are critical. These processes are essential for the safe and controlled production of TNT, nitroglycerine (NG), NGEL, nitrocellulose, and various propellant formulations.

During TNT, NG or propellant production, large volumes of nitric, sulfuric and hydrochloric acids must be handled safely and recycled at high purity. Efficient acid recovery systems, robust off-gas NOx treatment, and corrosion-resistant equipment are fundamental to stable plant performance and long-term reliability.

Engineering & Equipment for Nitration and Acid Recovery

De Dietrich provides complete solutions for the chemical steps that support energetic-material manufacturing. With decades of experience in corrosive environments, we design and deliver package solutions, including nitration blocks, acid concentration and recovery systems, NOx treatment units, purification sections and downstream separation.

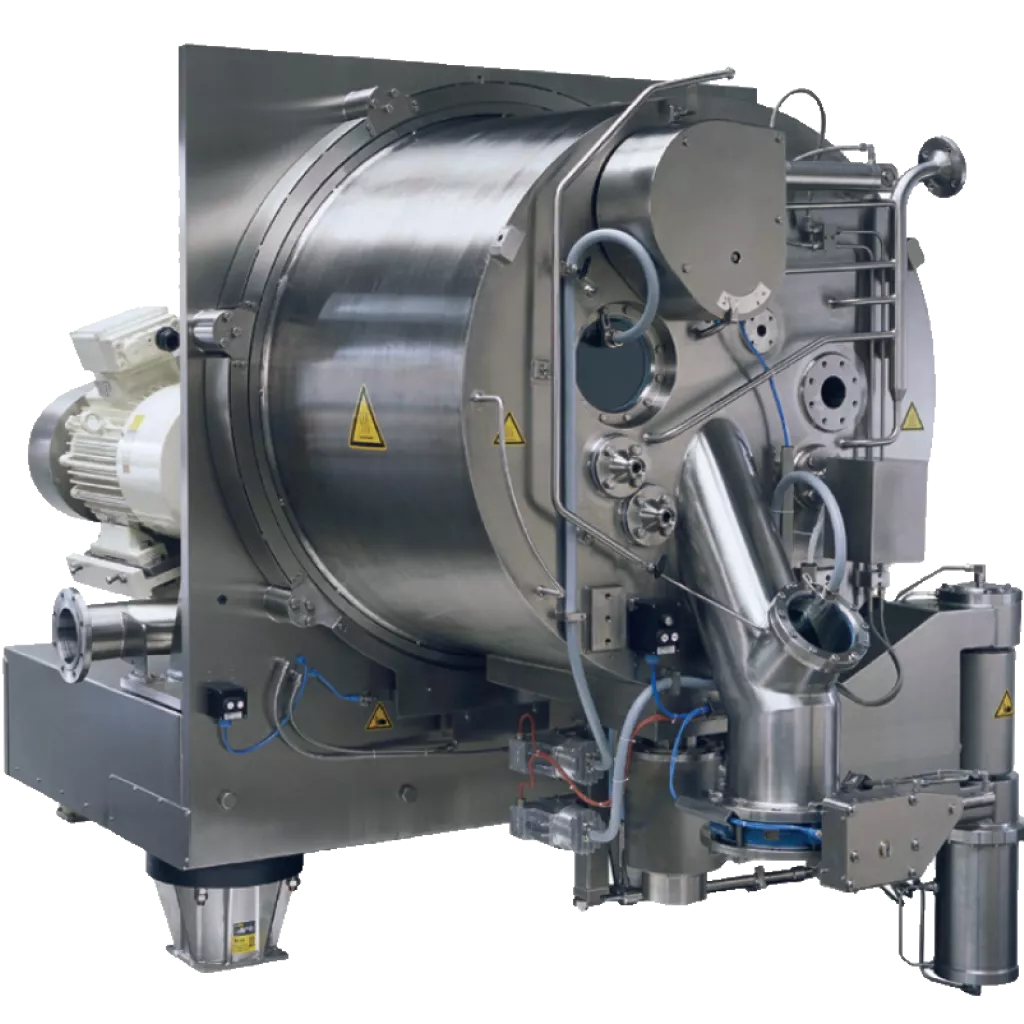

Our portfolio includes glass-lined reactors, borosilicate glass systems, filter-dryers, centrifuges, evaporators, scrubbers, and high-efficiency acid recovery plants capable of reaching up to 99% purity.

When required, we integrate specialised third-party equipment to deliver the most efficient configuration for TNT, NG, nitrocellulose or propellant-related processes.

From process definition and P&ID development to installation and start-up, De Dietrich provides a single point of contact for your entire project, guaranteeing proven performance, safety, and regulatory compliance.

Chemical Processes Behind Energetic Materials

The production of TNT, nitroglycerine (NG), NGEL, nitrocellulose and propellants requires strict control of exothermic reactions, corrosive acids and off-gas emissions.

Key operations include:

- Nitration of energetic molecules (Batch or continous process)

- Acid recovery & concentration (nitric, sulfuric, hydrochloric)

- NOx treatment and off-gas scrubbing

- Washing, separation & purification

- Thermal control and safe reaction management

All these steps demand robust engineering and equipment designed for corrosive and high-risk environments.

Package solutions & Corrosion-Resistant Equipment

De Dietrich provides complete process solutions, from P&ID development to commissioning. Our portfolio covers all critical stages:

- Glass-lined and borosilicate reactors

- Filter-dryers and centrifuges

- Evaporators & short-path distillation

- Acid concentration & recovery systems

- Scrubbers and NOx treatment equipment

- High-alloy, corrosion-resistant materials

- Continuous flow reactor

We also integrate third-party technologies when required to provide the optimal plant configuration.

Key assets

Package solutions for nitration, separation, distillation and acid recovery

Acid recovery up to 99% for nitric and mixed-acid systems

Process guarantee for acid recovery plants

Single partner for engineering, equipment & integration

Corrosion-resistant materials: glass-lined, borosilicate, alloys

Thousands of plants already installed worldwide