Engineering and Equipment for Critical Nuclear Operations

The nuclear sector demands uncompromising reliability, material resistance, and qualification discipline.

From harsh chemistries to radioactive environments, processes must be engineered to operate safely over decades.

De Dietrich provides the technologies and methodologies required to support these constraints, enabling operators to run critical chemical, separation, and waste-handling operations with confidence.

Integrated Process Capabilities for Nuclear Environments

De Dietrich delivers a full spectrum of process equipment and engineered solutions tailored to nuclear conditions, covering:

- Reaction and dissolution in corrosive media

- Gas treatment including NOx and HCl scrubbers proven in nuclear sites

- Liquid-liquid extraction for solvent separation

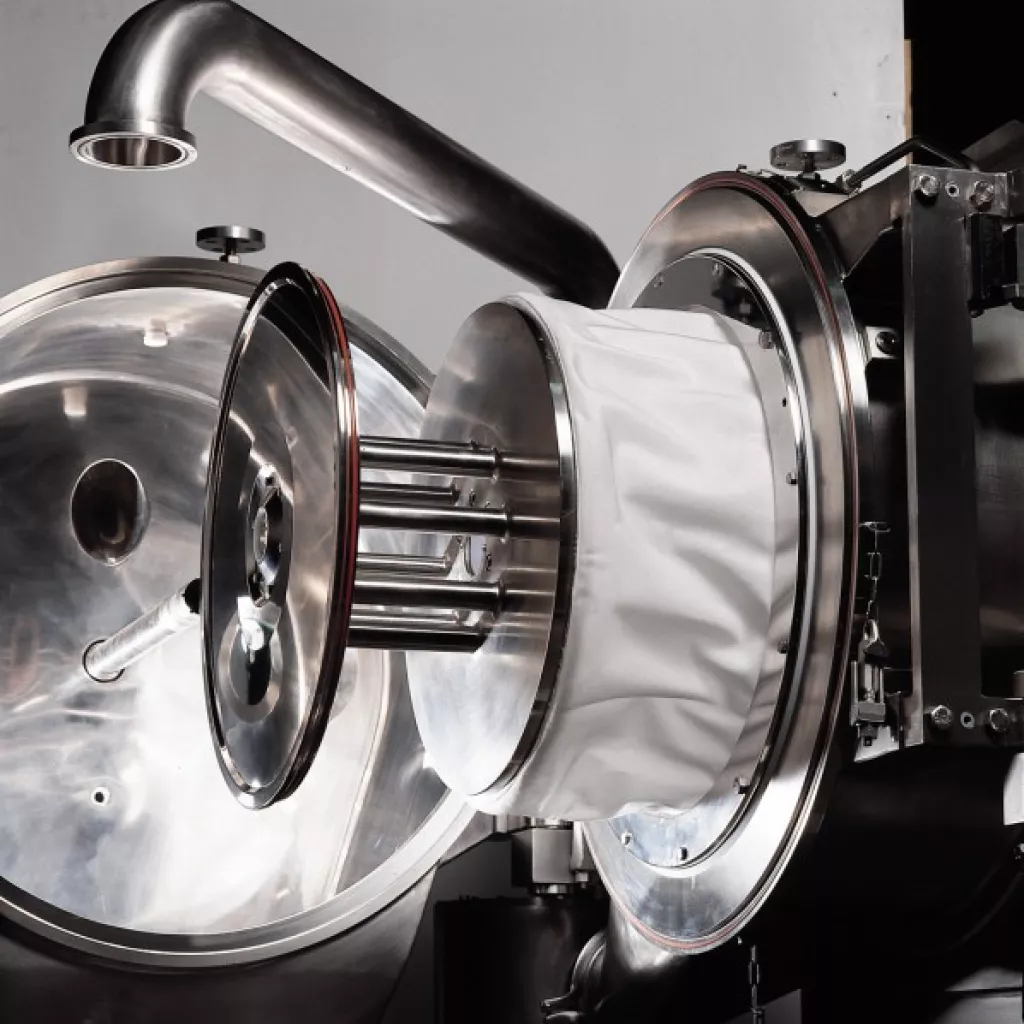

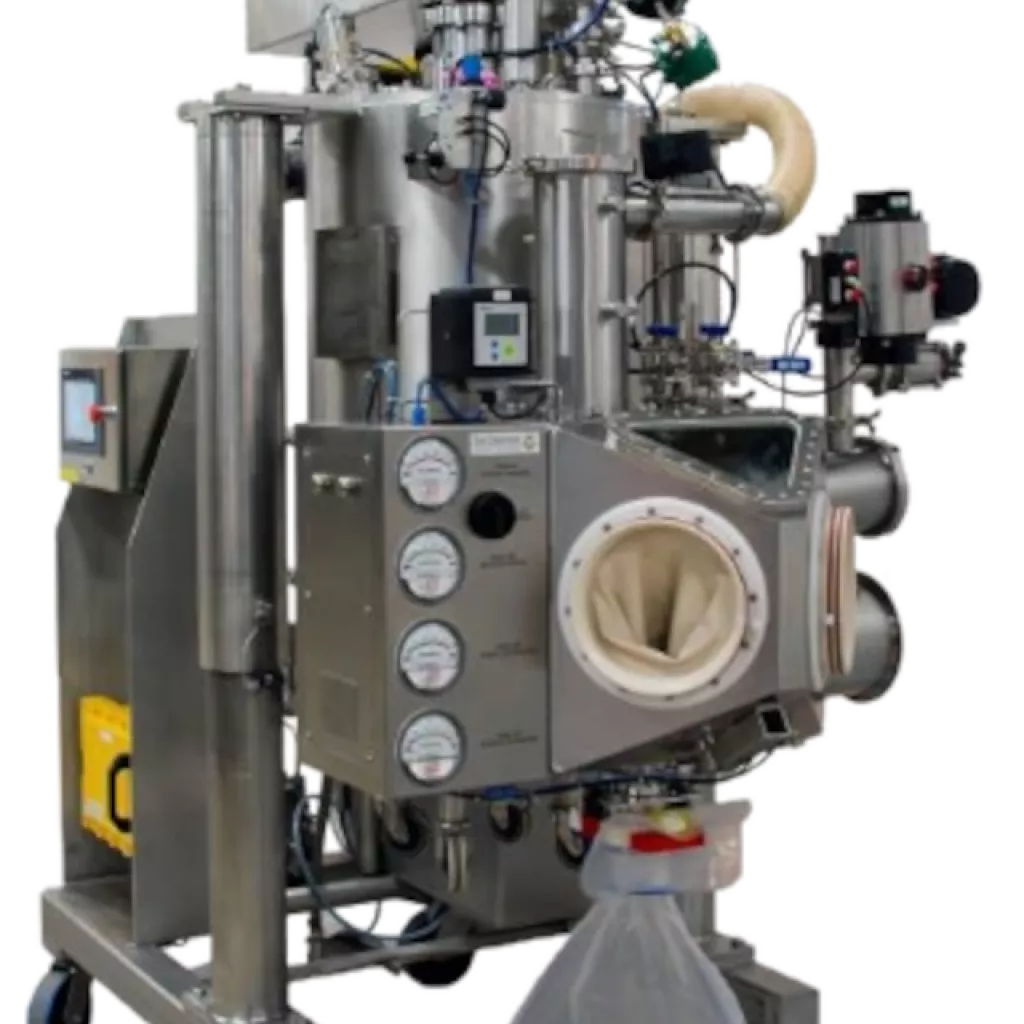

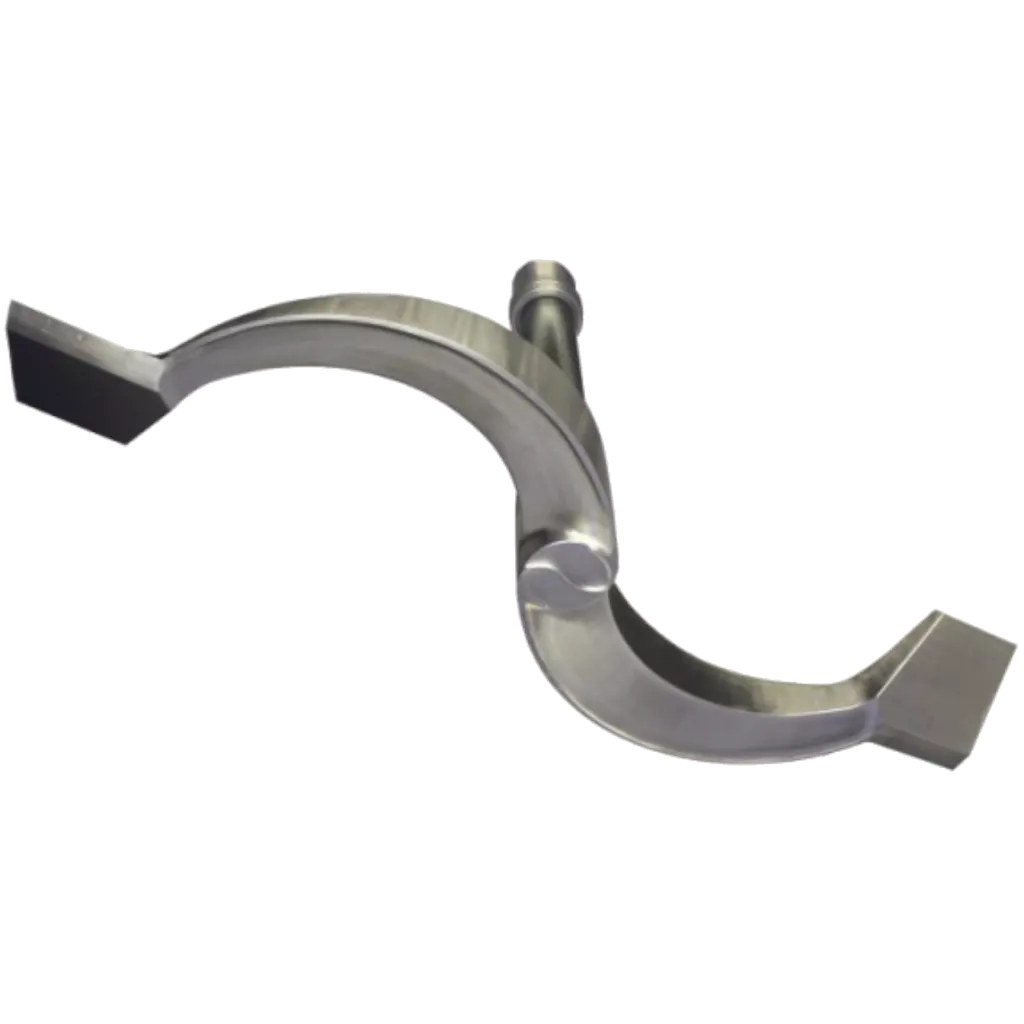

- Solid-liquid separation via centrifuges, nutsche filters-dryers, and vacuum dryers

- All compliant with containment, for example pack-off stations up to OEB 6 for dangerous powders

These systems are designed for chemical resistance, containment integrity, and long-term operational stability — three decisive factors for nuclear users.

Modular and Scalable Solutions for SMR and Nuclear Process Development

The rise of Small Modular Reactors (SMRs) reshapes equipment requirements: units must be compact, modular, testable, and certifiable before deployment. This shift favors suppliers capable of delivering pilotable engineering, not just machines.

PGS teams at De Dietrich design process skids and pilot units that support:

- Early validation of chemical steps linked to fuel-cycle innovations

- Testing of extraction media, slurries, or ion-exchange resins under relevant conditions

- Scalable plant concepts that evolve from lab demonstration to industrial implementation

- Integration of external modules when a project requires expertise outside the group — an approach rarely mastered in the nuclear field

These capabilities enable nuclear stakeholders to de-risk investments, accelerate qualification, and align development timelines with SMR deployment strategies.

Proven Track Record and Recognized Innovation in the Nuclear Sector

Nuclear operators expect evidence, not claims. Over the last decades, De Dietrich has built a sustained presence in the nuclear environment, combining corrosion-resistant equipment design, process engineering expertise, and long-term service capabilities that match the sector’s stringent qualification cycles. Our technologies are not experimental — they are deployed, tested, and improved within demanding industrial contexts.

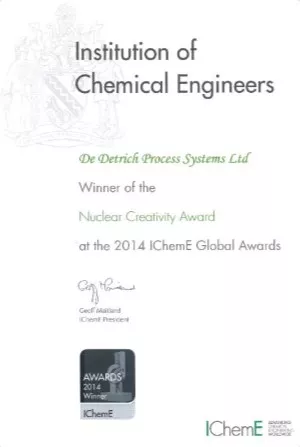

This historical footprint was formally acknowledged when De Dietrich received the IChemE Nuclear Creativity Award (2014) for the development of specialized glass scrubber columns engineered for Sellafield — a site emblematic of high-complexity nuclear chemistry.

This award validated our capacity to innovate within a conservative industry, where new solutions are accepted only once they have demonstrated reliability, compliance, and operational value.

more information in this video

This combination of legacy, proven technology, and documented innovation positions De Dietrich as a trusted partner capable of supporting both established nuclear infrastructures and emerging architectures, including SMRs.

Need an improvement of your process in nuclear industry?

Our teams are ready to help you!