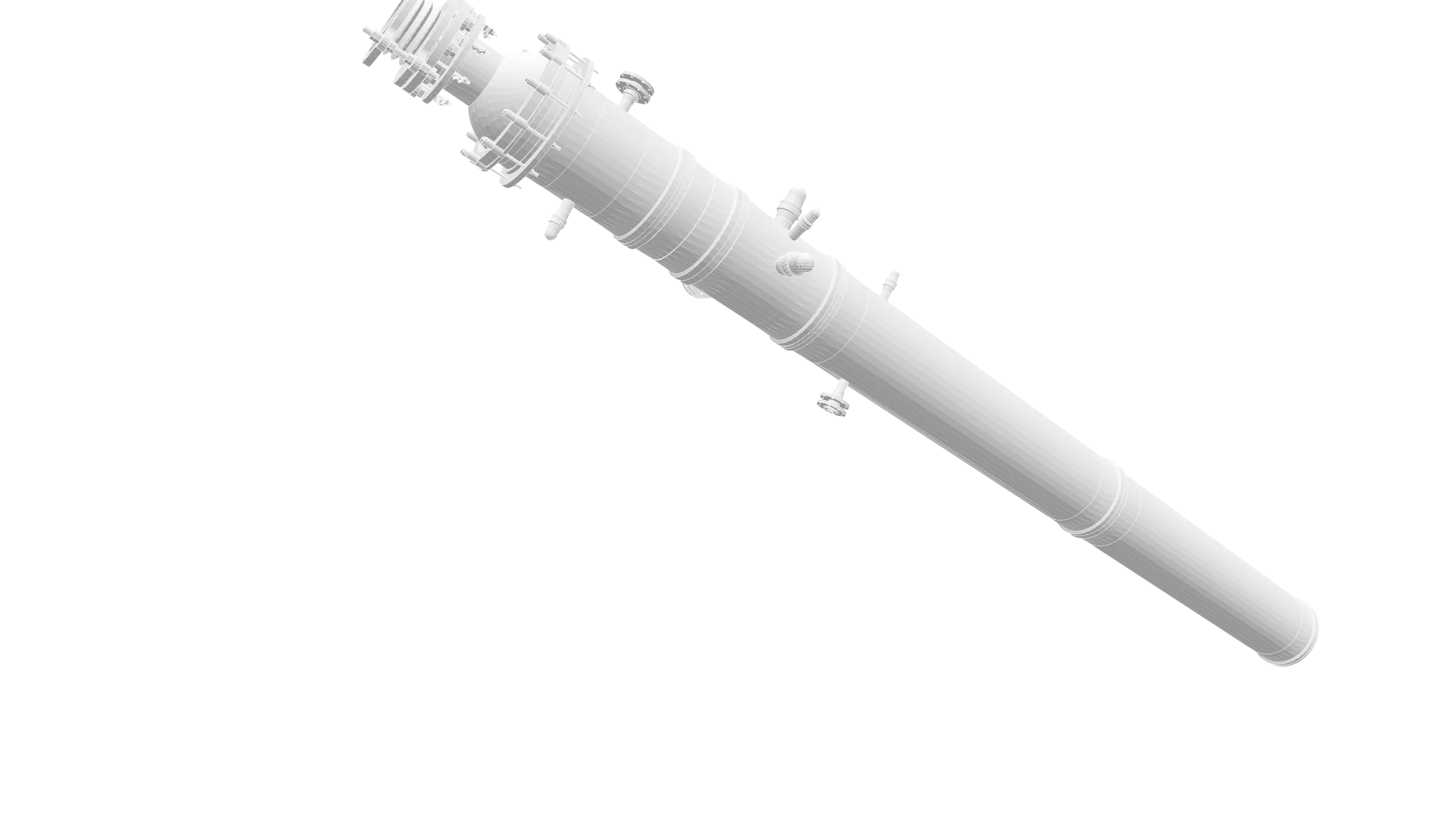

Extraction Columns

Continuous product separation

The cost efficient solution for multi-stage extraction processes

Cost efficient realisation of multi-stage processes

The more theoretical separation stages have to be realized the more an extraction column becomes economically interesting compared to mixer-settlers since increasing the number of theoretical separation stages just increases the height of the column.The 2 liquid phases pass the column by gravity in a counter current manner. In extraction columns the same 2 process steps as mixing and settling have to be realized per separation stage.

The mixing process in a column can be carried out in different ways differentiating the types of extraction columns.

The settling processes in columns is mostly less efficient as in mixer-settlers since back mixing and dispersion entrainment are less avoidable and more or less fixed by the selection of the mixing process and hence the type of extraction column.

De Dietrich Process Systems offers different column types as:

Therefore the column type has to be selected very carefully according to the specific extraction process. This is mostly done either through existing experience for a given extraction process or supported by trials which we can carry out in our experimental hall. |

PULSED EXTRACTION COLUMNS

As the name says, the way the dispersion energy is introduced into this column is done by means of a pulsator. We provide pulsed columns from DN50 to DN600 with borosilicate glass 3.3 as preferred column material. The total two-phase liquid hold-up in the column is pulsed up- and downwards. The flow through the internals as sieves or a packing generates the mixing process.

Packed columns

As packing both random and structured packings are used. To be consistent with the corrosion resistance of our columns made of borosilicate glass 3.3 we prefer RASCHIG-rings in different sizes and our unique structured packing DURAPACK® both made of borosilicate glass 3.3. Packed columns have no separate settling column zones so that they are more favorable for fast phase separation processes but require only relatively low investment costs. Again it’s best to base the selection of the right packing on trials for the given process.

Sieve tray columns

Contrary to packed columns the settling zones in sieve tray columns can be enlarged by the distance of the sieves. The sieves are fixed on a central shaft with a minimum or sealed gap to the inner glass wall of the column. For sieve-tray columns not only the distance of the trays can be varied but also the free cross area from 7 to 50%. As material of construction stainless steel is most economic if no corrosion issues are to be expected otherwise the sieve trays can also be realized in borosilicate glass 3.3 and PTFE.

KARR COLUMNS In a pulsed extraction column the liquid hold-up is pulsating up- and downwards. In a KARR-type column it’s the central shaft with the sieves oscillating. Frequency and stroke length of this movement can be adapted to the process with our KARR-type columns available up to DN600. The sieves have normally a large free cross area of 50% and the gap to the wall is larger than in sieve tray columns due to their movement. Together with the relatively easy dismantling of the shaft this column type has a certain preference when solids are present in the process. | |

STIRRED CELL EXTRACTOR - RZE The QVF®- RZE Column has been developed by De Dietrich Process Systems. As in a RDC column a central shaft rotates and stators are installed in the column. Instead of discs real stirring elements are fixed to the shaft and the stators are equipped with notched weirs around their inner edge. The stirring elements have a higher mixing efficiency as discs and the notched weir improve phase separation enlarging the range of throughput. The stirrer shaft and the stators are combined in single modules made of stainless steel or other metals. Joining these modules give the required active length in the extraction column made of borosilicate glass 3.3. |

ROTATING DISK CONTACTOR - RDC In an RDC-column the central shaft equipped with fixed discs is rotating. In addition to that annular rings, so called stators are placed on the inside of the column always in the middle of the distance between two discs. These stators can either be made of metal and inserted into the column or can be integrated in column made of borosilicate glass. The discs have a smaller diameter than inner diameter of the stators so that the shaft can be easily dismantled. Diameters and distances have to be adapted to the process. During operation only the rotating speed can be altered beside the throughput.

HOW TO FIND THE BEST SOLUTION ? Beside theoretical calculations and extraction expertise gathered along the history of De Dietrich Process Systems will be pleased to carry out trials in our experimental hall to develop the optimum process and to select the most suitable extraction equipment for you. Borosilicate glass 3.3 is an ideal material for extraction equipment as the process can be optimized while easily looking visually into the process. |

Documents to download

Request a download

In order to process your brochure request efficiently, we kindly ask you to provide the required information through our form.